- MIG

- TIG

- MMA

The Different Types of Welding Joints: A Comprehensive Guide

By Sarah Mazlin

08/12/2025

10 minutes

Understanding the various types of welding joints is crucial to achieving the desired strength and quality in your projects. The main joint types include butt, lap, outside corner, fillet, and edge joints, with each offering unique advantages and being suited for different applications.

When welding, the type of joint influences the overall integrity and appearance of the final product. Butt joints are commonly used for simpler, flat surfaces, while lap joints excel in overlapping configurations. Corner and fillet joints are used for creating frames and structures, and edge joints come into play with sheet metal work.

Your approach to these joints directly impacts the strength and quality of your weld, from piping and construction to intricate metalwork.

What Is a Weld Joint?

The weld joint is where two pieces of metal are joined, and its quality dictates the ultimate strength of the assembled structure. The penetration of the joint refers to how deep the weld enters into the base material, which is critical for the joint’s capacity to handle load and resistance.

- Butt joints are employed when the edges of two metal pieces are placed side-by-side or end-to-end and welded along a single seam. Their simplicity makes them suitable for a wide range of thickness levels, from thin sheet metal to thicker plates.

- Lap joints involve overlapping the pieces and welding at the points of intersection. They distribute force over a larger area and are preferable for thinner metals.

- Groove welds are used when the metals are too thick to achieve full penetration with a square butt only. Having grooved edges allows for the arc to reach deeper into the material to then be filled with weld material, improving penetration for a stronger joint.

- Fillet welds are common in tee joints, where two pieces intersect at an angle (usually a 90° angle) and, therefore, require welding on one or both sides of the intersection.

The type of weld joint will depend on what the weld will be used for, whether it needs to be aesthetic, and how thick the material is. The type of joint needing to be welded can play a role in deciding the welding process used, as some are better suited to certain positions.

The Different Types of Welding Joints

There are five basic types of weld joints, each with its own characteristics, designed to manage different loads and configurations.

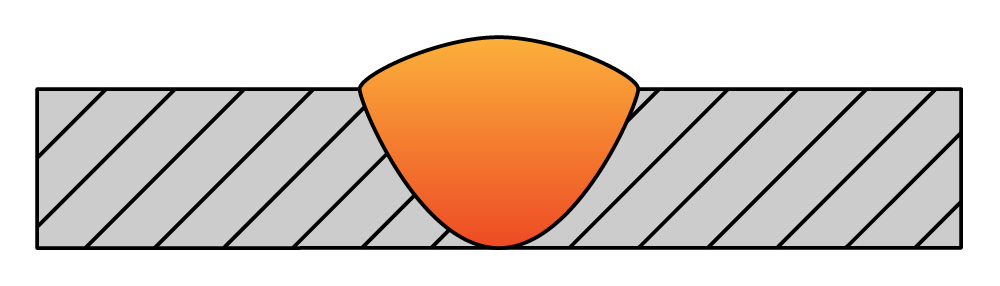

Butt Joint

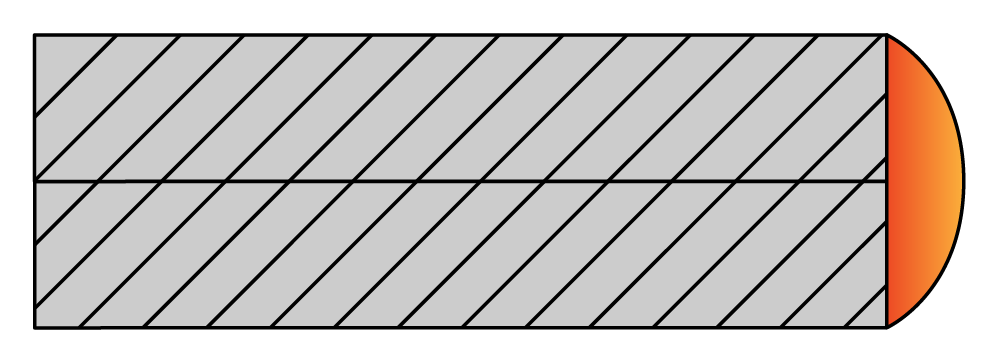

A butt welding joint is made when two pieces of metal are laid parallel on their sides or ends at roughly a 180° angle. The metal is ‘butted together’, giving it its name.

Butt welds can be used on a range of thicknesses, and a lot of the time, they won’t need any prep. The metal can be placed next to each other and welded immediately, which is known as a square butt weld.

However, once the metal gets too thick, some preparation in the form of bevelling or creating a groove is necessary to maintain proper weld penetration.

Butt welds are one of the most common types of welding joints and are often used in pipeline and plate construction.

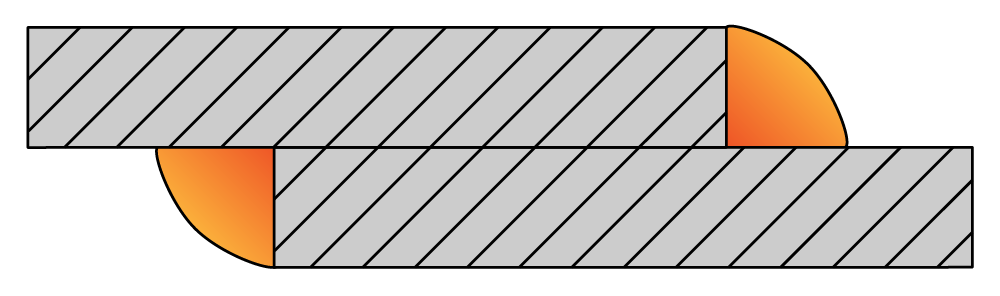

Lap Joint

A lap welding joint is made when two pieces of metal overlap and are welded along the seam. Lap joints are used when connecting parts with differing thicknesses or when a butt joint is not feasible.

Lap joints are often used for repairs or when more reinforcement is needed in the weld.

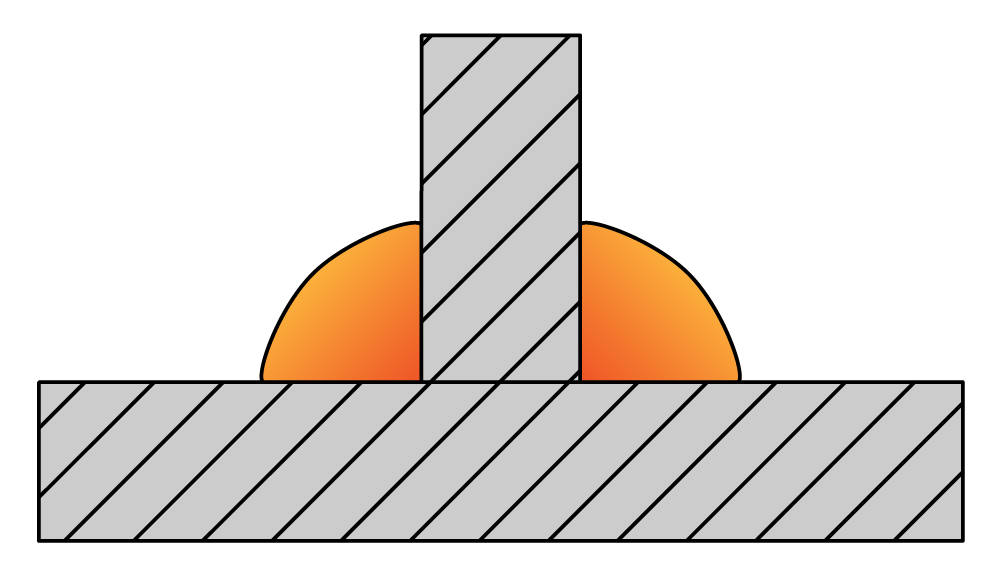

Tee Joint

A tee welding joint is made when two pieces of perpendicular metal are joined at a right angle (90°), resembling the letter ‘T’. T-joints are a type of fillet weld used across many structural steel applications, including pipe or tube welding and manufacturing.

Fillet welds, and therefore T-joints, are one of the most used joints across all types of arc welding. Depending on the load, they can be welded on one side or both, and the joint design and preparation will vary depending on the material thickness and the work angle.

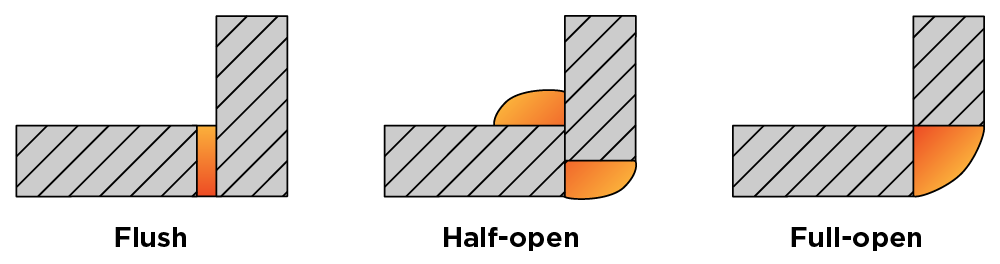

Corner Joint

A corner welding joint is made when two pieces of metal are joined at the corner at a 90° angle to form an ‘L’ shape.

Corner joints have two distinct types: an open corner joint with a V groove space between the pieces and a closed or flush corner joint where the ends meet. Closed corner joints are a bit more difficult to weld, but they generally offer a higher mechanical strength.

Corner joints are commonly used in box, table or frame fabrication to ensure rigidity in the corners. The inside corner joint is also another type of fillet weld.

Edge Joint

An edge welding joint is made when two pieces of metal are joined side-by-side at their edges. The edge itself or the entire way around the joint can be welded to form an edge joint. While not typically the main structural joint, they’re often used for sheet metal assembly and adding stiffness with a groove joint technique.

These types of joints each have a specific weld joint design depending on their intended function. The kind of joint will impact your weld’s strength, aesthetics, and application.

Joint Preparation & Assembly

As well as the joint type and its configuration, you’ll also need to think about the preparation of the joint. This isn’t always needed if you’re working with thin materials, but if you’re working with thicker materials, you’ll need to prep the joint.

Proper joint preparation and assembly are essential for creating a strong weld. The process involves preparing the edges of the plates, understanding the joint design, and – if you’re working on job sites – interpreting welding symbols and notations.

Edge Preparation

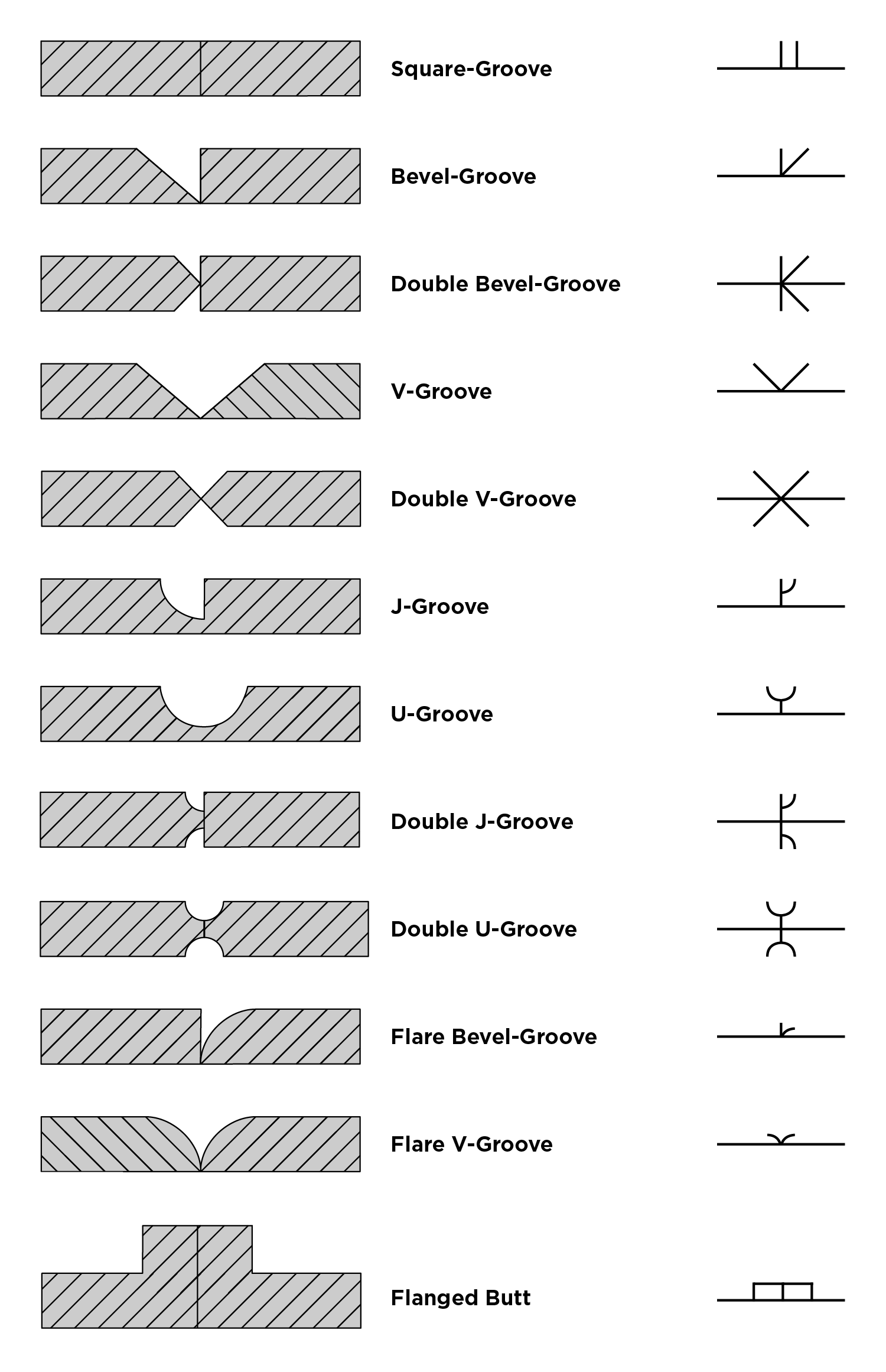

The edge or joint preparation depends on the thickness and type of the materials to be joined. For plates thicker than 5mm, you’ll need to bevel the edges to get proper weld penetration. Several types of grooves can be used to prep the plate:

- Square groove

- Bevel groove

- Double bevel groove

- V groove

- Double V groove

- J groove

- Double J groove

- U groove

- Double U groove

- Flare bevel groove

- Flare V groove

- Flange

As well as prepping the edges, this is when you’ll also decide on the root opening size if any is needed. The root gap is how far apart the two pieces are from each other. Most welds don’t have any root gap. The thicker the material, the more root gap will be needed to get penetration all the way to the root of the weld.

Your choice depends on the welding position and the base metal thickness. The bevel angle and root opening need to be right to avoid getting any defects in the weld. It will also depend on whether you’re following engineering plans because if you are, you’ll need to match those instructions.

Joint Design Considerations

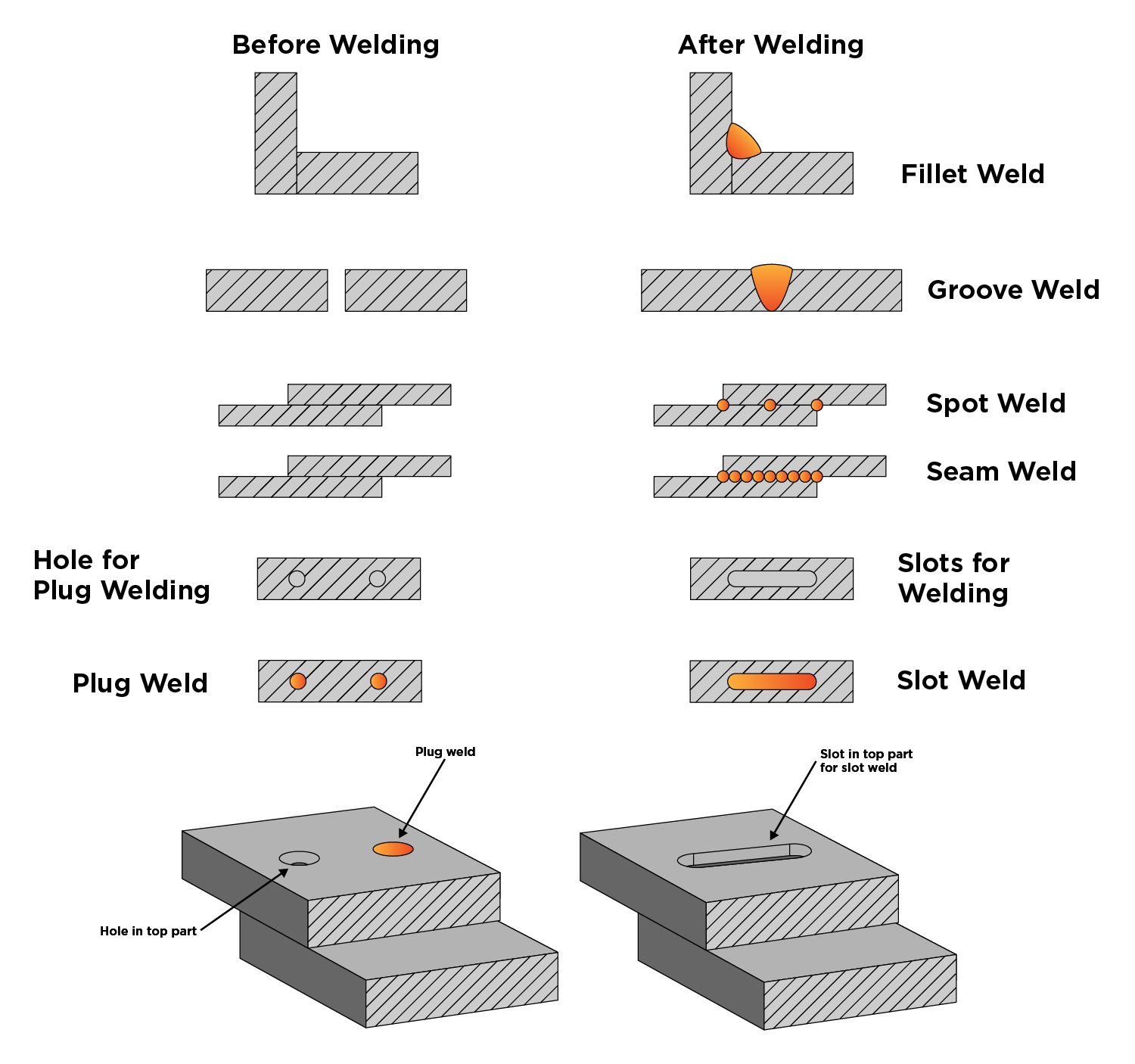

The joint design and weld fit up also play a role in the strength of the final weld. On top of the five main joint types, butt joint welding, lap joint welding, corner joint welding, edge joint welding, and T-joint welding, there’s also the weld fit up. These different fit ups or ways to weld the joints together include:

- Fillet welds

- Groove welds

- Slot welds

- Spot welds

- Plug welds

- Seam welds

The part’s application and its necessary load bearing will determine the best joint design for each weld.

Welding Symbols & Notations

While not a concern for DIY and home hobby welders, welding codes and symbols are needed to execute the correct weld when working on job sites and following plans.

A welding symbol provides detailed instructions on the type of weld, its size, length, and other specifications. These weld symbols are standardised, with elements like arrows, reference lines, and tails representing the grooves and specifications, such as the bevel angle or root opening.

You can create high-quality, strong, reliable welds with good edge preparation, proper joint design, and by following welding symbols.

Checking the Quality of Your Weld

The durability and safety of the weld will depend on its quality. When working on projects around the house or anything that isn’t load-bearing, structural, medical, or in the food industry, checking the weld’s quality isn’t always necessary.

Various factors, like penetration and adherence to welding standards, will determine a joint’s structural integrity. You can test the quality of your welds through destructive and non-destructive testing methods.

Testing & Ensuring Weld Quality

One destructive testing method you can use is to try and snap the weld. You can do this by placing your welded piece in a vice and bending it until it breaks. Depending on the material thickness, it shouldn’t break, or it should take immense pressure before failing.

Non-Destructive Testing (NDT) methods are used to check for the absence of defects without damaging the workpiece. Standard NDT methods include visual inspection, which is where you examine the weld for surface defects like porosity. More sophisticated techniques like ultrasonic testing or X-rays can reveal internal flaws like voids or inclusions.

Another aspect of quality assurance is making sure there’s proper reinforcement of the joint and preventing over-welding. Over-welding can lead to unnecessary stress concentrations, which will cause cracks to form and is a waste of welding material. Dimensional accuracy is equally important, ensuring that welds are strong and meet the precise specifications of the job at hand.

By applying quality controls and testing methods, you can reduce the risk of weld failure and improve the safety and longevity of welded structures and components.

Practical Considerations & Applications

When welding your project, you need to consider factors like the required strength, the materials involved, and the specific application.

Selecting the Right Joint for the Job

The type of joint you select for your welding job is dictated by the fabrication requirements and the desired mechanical strength of the assembled structure. When dealing with structural steel, joints that require a bevel groove weld are often chosen for their ability to distribute stress over a wider area, providing a stronger weld.

- Butt joints: ideal for simple, flat surfaces where pieces are aligned in the same plane

- Lap joints: used when two pieces overlap and are welded at the edges

- Tee joints: common in construction when a perpendicular strength is needed

- Corner joints: effective when two pieces come together at a right angle

- Edge joints: typically used for sheet metal with flanged edges

Each joint requires thoughtful consideration of work angle, base metals, and welding style.

Applications in Manufacturing & Construction

Manufacturing and construction projects require careful joint preparation and execution to ensure structural integrity. When applying welds in construction, the strength of a joint often takes precedence due to the demands for safety and quality.

- Fabrication often involves cutting and grinding before joining pieces together. Whether it’s a flange in a pipeline or the framework of a building, the right weld can mean the difference between endurance and failure.

- Filler material choice, backing techniques, and precise machining are critical, especially when dealing with heavy structural steel.

- Weld types are chosen based on their effectiveness in situations where metal needs to be joined at a variety of angles or when complex, multi-axis fabrication is involved.

Properly preparing the surface of the weld through grinding and cleaning, choosing a compatible welding method, and using the correct filler material will improve the joint’s mechanical strength and durability in manufacturing and construction applications.

Understanding the different types of welding joints is helpful for the success of any welding project. Each joint type has its own unique benefits and is best suited for specific applications.

Factors like the material being used, the position of the welding, and using the right welding technique for the joint type all work to achieve strong and durable welds. Armed with this knowledge, you can confidently carry out tasks with accuracy and efficiency, resulting in top-tier welding outcomes.